What was the German liner Imperator used for?

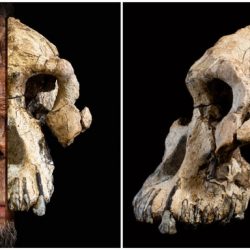

German liner Imperator at anchor, c. 1913, with the grandiose bow eagle of the Hapag company still in place. Seized as war reparations. Used as a troop transport for the United States from May 1919.

How much did it cost to rebuild the SS Imperator?

The ship’s funnels were reduced in height by 9.8 ft (3 m). Finally, 2,000 tons of cement was poured into the ship’s double bottom as ballast. This work cost £200,000, which had to be borne by the shipyard as part of their five-year warranty to the shipowners.

Where was the SS Imperator during World War 1?

Imperator was the first of a trio of successively larger Hamburg American liners that included SS Vaterland (later the United States Liner Leviathan) and SS Bismarck (purchased and renamed Majestic for the White Star Line transatlantic passenger service). During World War I, the ship remained in port in Hamburg.

When did the Imperator return to Vulkan shipyard?

In October 1913, Imperator returned to the Vulkan shipyard to facilitate drastic work to improve handling and stability, as it had been discovered that her centre of gravity was too high (see metacentric height ).

German liner Imperator at anchor, c. 1913, with the grandiose bow eagle of the Hapag company still in place. Seized as war reparations. Used as a troop transport for the United States from May 1919.

Which is the C Deck on the SS Imperator?

The C, or promenade deck, is devoted to staterooms and the larger private suites, the finest of which, the Imperial suite, comprises twelve rooms and a veranda deck. This private deck is inclosed and serves as a sun parlor in the Winter season.

Why was the SS Imperator built in Hamburg?

The object of the Hamburg-American Line in building the Imperator was to give her sufficient speed to land her passengers in London or Paris on the sixth day and Hamburg and Berlin on the seventh day from New York.

The ship’s funnels were reduced in height by 9.8 ft (3 m). Finally, 2,000 tons of cement was poured into the ship’s double bottom as ballast. This work cost £200,000, which had to be borne by the shipyard as part of their five-year warranty to the shipowners.